Agile as a methodology has other frameworks and methodologies that are subsets to it. Think about them as various flavors of the methodology.

While methodologies all adhere to the Agile Manifesto, they each have their different nuances and method of application.

Lean and Kanban are two popular methodologies under the Agile approach umbrella that are used in the field of project management and software development.

While both of these methodologies aim to optimize processes and increase efficiency, they differ in their focus and application.

In this blog post, we will explore the key differences between Lean and Kanban, their advantages and disadvantages, and when each methodology is best suited for your project and team.

Introduction to Lean Methodology

Lean is a methodology that originated in Japan by Toyota in the 20th century. The methodology was originally used in the manufacturing industry but was later adapted for use in other fields over time.

The goal of Lean is to create a smooth and efficient process that delivers value to customers as quickly and effectively as possible.

This is achieved by identifying and eliminating waste and continuously improving the process based on feedback and data.

One of the key principles of Lean is the idea of “flow.” This means creating a process that allows work to flow smoothly and continuously, without bottlenecks or interruptions.

Teams using Lean aim to create a process that is “pull-based” rather than “push-based,” meaning that work is started only when there is a demand for it.

Another important aspect of Lean is visual management. Teams using this methodology use visual aids, such as boards or kanban systems, to see the flow of work and identify areas for improvement.

By using visual management, teams are able to see the big picture and make data-driven decisions to optimize their process.

Introduction to Kanban Methodology

Kanban is a visual system that is used for managing and optimizing work processes.

It originated in the manufacturing industry in Japan and has since been adopted by organizations across various industries for software development, marketing, HR, and more.

One distinguishing feature of this methodology that sets it apart from others is its focus on continuous delivery and improvement.

Rather than following a set timeline or rigid process, Kanban allows teams to adjust and improve their workflow as they go.

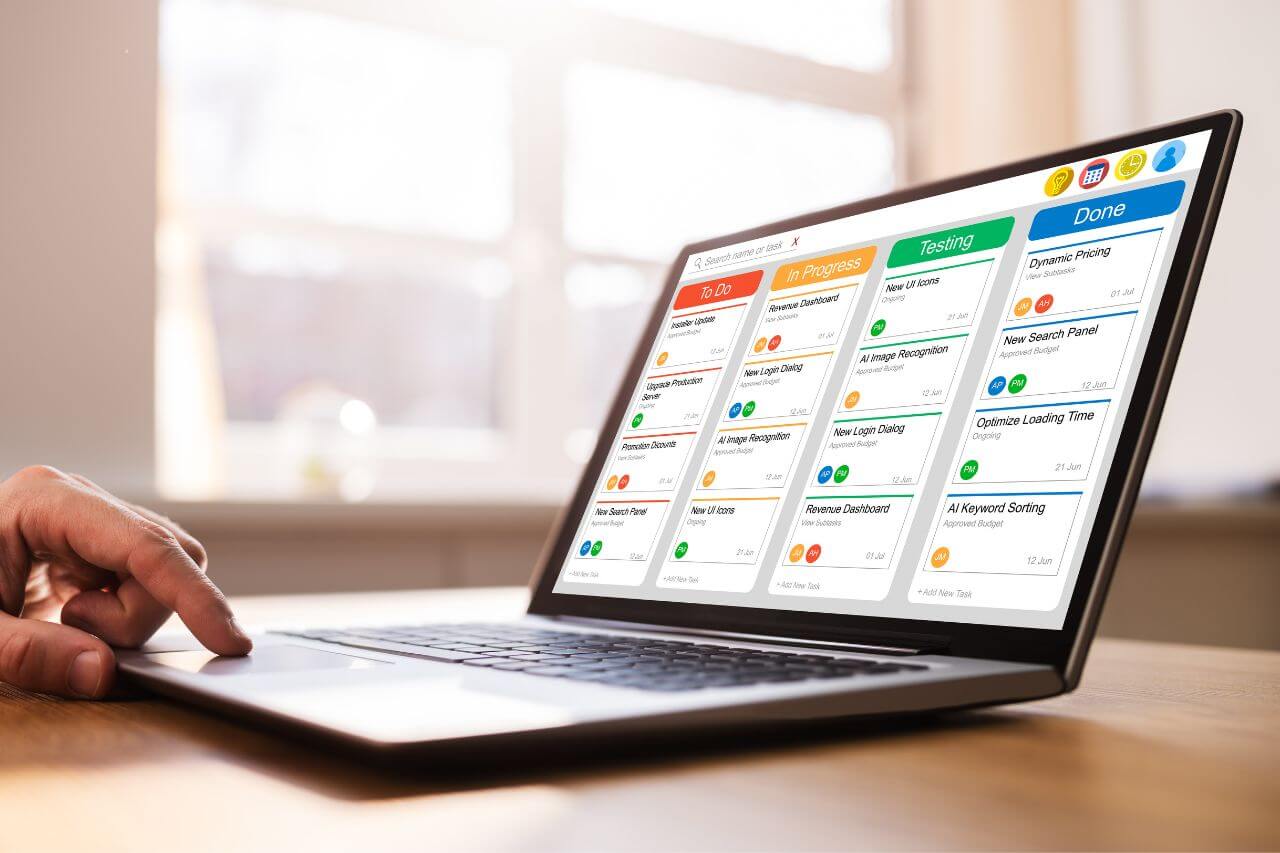

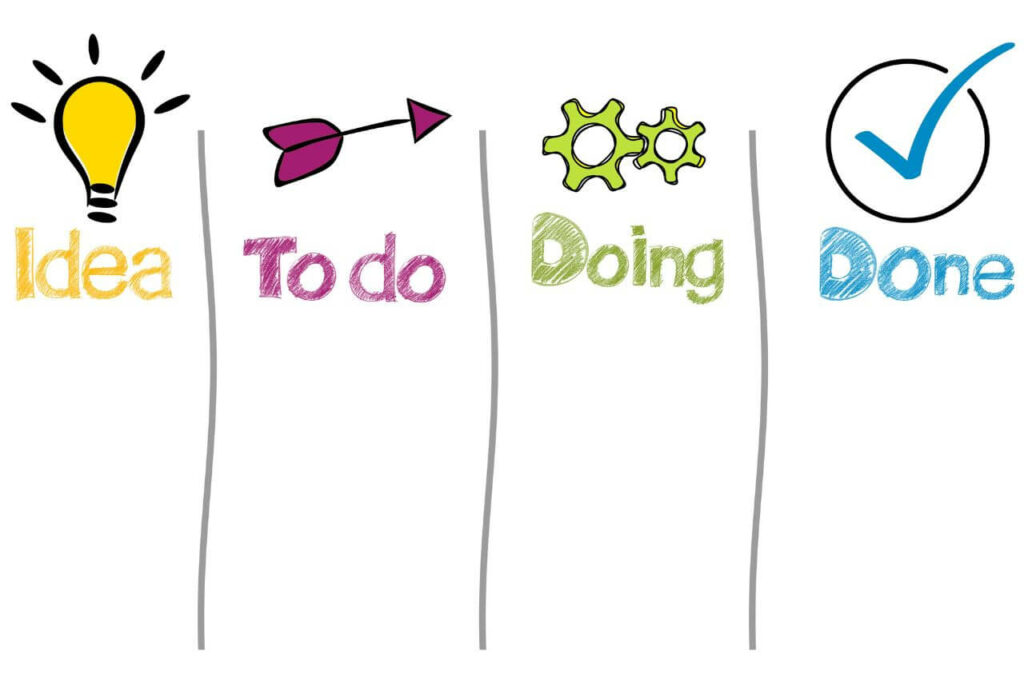

In a Kanban system, tasks are represented by cards on a board, and the board itself is used to visualize the flow of work.

The board is divided into columns that represent different stages of a task, such as “to do,” “in progress,” and “done.”

As tasks move from left to right, the team is able to see what’s been completed and what still needs to be done.

One of the key principles of Kanban is limiting work in progress. This means that teams only start on a new task once they’ve finished the one they’re currently working on.

By limiting the number of tasks being worked on at once, teams can reduce the risk of overload and ensure that each task is given the attention it needs.

Differences Between Lean and Kanban

When it comes to managing different projects and teams, it’s important that you choose the methodology or approach that best fits your needs.

In order to do this, you need an understanding of the core of the different methodologies, and how they differ from each other.

By understanding these key differences between Lean and Kanban, you can make an informed decision about which methodology is best for your team and your project.

Whether you choose Lean or Kanban, both methodologies prioritize continuous improvement and are designed to help teams deliver value to customers effectively and efficiently.

Here’s a breakdown of the key differences between Lean and Kanban:

1. Focus

Lean has a focus on eliminating waste and maximizing value, while Kanban is focused on managing and optimizing work processes.

2. Approach

Lean takes a more structured approach, using data and metrics to drive continuous improvement, while Kanban allows teams to adjust and improve their workflow as they go.

3. Visualization

Both Lean and Kanban utilize visual aids, but Kanban places a stronger emphasis on visualizing the flow of work.

4. Work in Progress

Kanban limits work in progress to reduce the risk of overload, while Lean focuses on creating a smooth and continuous flow of work.

5. Timing

Lean often follows a set timeline or rigid process, while Kanban is flexible and allows teams to work at their own pace.

Advantages of Lean Methodology

There are many reasons why teams all over the world choose to use the Lean methodology.

You can also take advantage of these benefits to create processes that deliver value to customers in a fast and effective manner, while also continuously improving over time.

Whether you’re in manufacturing, healthcare, software development, or another industry, Lean can help your team work better and achieve more.

Here are a few of the key advantages:

1. Elimination of Waste

One of the core goals of Lean is to eliminate waste, which can lead to more efficient and effective processes for your projects.

2. Continuous Improvement

Lean places a strong emphasis on continuous improvement, which can help you and your team stay ahead of the competition and better meet customer needs.

3. Structured Approach

The structured approach of Lean can help teams stay organized and on track, making it easier to deliver results that are vehicles of value.

4. Data-Driven Decisions

By using data and metrics, teams can make informed decisions that drive continuous improvement and ensure that their processes are optimized.

5. Increased Value for Customers

By focusing on delivering value to customers and eliminating waste, Lean can help teams create a process that is more efficient, effective, and customer-friendly.

Disadvantages of Lean Methodology

While the Lean methodology offers lots of benefits, it’s not without its drawbacks.

By being aware of these challenges, you can prepare for and mitigate potential difficulties when implementing Lean.

Here are a few of the challenges that teams may face when using the Lean methodology:

1. Inflexibility

Lean methodology has a relatively structured approach and this can make it difficult for teams to adapt to changing circumstances or new opportunities.

2. Time and Resource Intensive

Implementing Lean can be time and resource-intensive, which can be a challenge if you are working with limited resources or tight timelines.

3. Resistance to Change

Some team members may resist change and be uncomfortable with the idea of continuously improving and streamlining processes.

4. Focus on Efficiency

While efficiency is important, the focus on eliminating waste and streamlining processes in Lean can sometimes come at the expense of creativity or innovation.

5. Complexity

Lean can be a complex methodology, which can make it challenging for some teams to implement effectively.

Read Also: Scrum Master vs Project Manager: Knowing Which Role is Right for You

Advantages of Kanban Methodology

The Kanban methodology also offers a ton of benefits to teams looking to improve their work processes.

By taking advantage of these benefits, you and your team can streamline your work processes, increase efficiency, and continuously improve in a flexible and agile manner.

Whether you’re working on a software development project, a marketing campaign, or another type of work, Kanban can be a powerful tool for getting results.

Some of the key advantages of the Kanban methodology include:

1. Flexibility

Kanban is a flexible approach that can adapt to changing circumstances and accommodate different team needs.

2. Visualization

By using visual aids like boards and cards, Kanban makes it easy to see the status of work items and track progress.

3. Continuous Improvement

Like Lean, Kanban places a strong emphasis on continuous improvement, but in a less structured manner, allowing teams to continuously improve their processes in real-time.

4. No Prescribed Process

Unlike some methodologies, Kanban doesn’t prescribe a specific process or set of steps, which can make it easier for teams to be more agile and customize the approach to their needs.

5. Easy to Implement

Kanban is a relatively simple and straightforward methodology, which makes it easy for teams to get started and see results quickly.

Disadvantages of Kanban Methodology

These are some of the drawbacks to implementing and using the Kanban approach.

1. Lack of Structure

For some teams, the unstructured nature of Kanban can be a disadvantage. Without a set process to follow, teams may find it difficult to establish a consistent and efficient workflow.

2. Requires Discipline

Kanban relies on the discipline of team members to follow the process, which can be challenging for some teams who may struggle with accountability.

3. Limited Visibility

Unlike Lean, which often uses detailed metrics to track progress, Kanban’s visual approach can sometimes limit visibility into key performance indicators.

4. May Not Scale Well

While effective for small teams, Kanban can be less suited to larger organizations or complex projects, as the lack of structure may make it difficult to manage and coordinate the work of multiple teams.

5. Difficult to Monitor Progress

Without clear metrics or process guidelines, it can be challenging for teams to monitor progress and measure success.

Lean vs Kanban: When to Use Lean

So, when is it best to use the Lean methodology? Here are a few scenarios when Lean can be the most effective:

1. Large-Scale Projects

For big, complex projects that involve multiple teams and departments, Lean’s structure and process-driven approach can help ensure everyone is working towards the same goal.

2. Companies with Defined Processes

If your organization already has established processes in place, Lean can help streamline and optimize these processes to drive continuous improvement.

3. Teams with Limited Collaboration

If your team is struggling with collaboration and coordination, Lean can help standardize processes and improve communication, helping everyone work together more effectively.

4. Companies with a Focus on Metrics

If your organization places a high value on data-driven decision-making, Lean’s detailed metrics and process tracking can help you stay on top of key performance indicators and make informed decisions.

Lean vs Kanban: When to Use Kanban

For Kanban, here are a few scenarios when it can be the most effective approach for you to use:

1. Teams with Interruptions

If your team frequently deals with changing priorities and urgent requests, Kanban’s flexible approach allows for quick and easy adjustments to accommodate these interruptions.

2. Teams with High Volumes of Work

If your team is facing a high volume of work, Kanban’s visualization tools and real-time updates can help manage the flow of work and prioritize tasks more effectively.

3. Companies with Limited Processes

If your organization doesn’t have well-defined processes, Kanban’s flexible and iterative approach can help teams work together more effectively and improve collaboration.

4. Teams with Complex Workflow

If your team is facing complex workflow issues, such as bottlenecks or handoff issues, Kanban’s visualization tools can help identify and resolve these problems in real-time.

Read Also: Extreme Programming (XP) vs Scrum: A Comparison of Agile Methodologies

Can Lean and Kanban Work Together?

Having seen the strengths and drawbacks of each of these methodologies, this is the next logical question. The simple and short answer is yes, Lean and Kanban can work together.

Although they have different approaches and focuses, they complement each other and can be used together to achieve better results so this doesn’t necessarily have to be this or the other.

Lean provides a continuous improvement process that aims to eliminate waste and improve the flow of work, while Kanban provides a visual system that focuses on optimizing the flow of work.

By leveraging the synergy between Lean and Kanban, organizations can achieve greater efficiency and effectiveness in their work processes.

How Can Lean and Kanban Work Together?

Now that you know that it’s possible to combine these 2 methodologies in a hybrid mode and get the best of both worlds, it’s important to know also know how to go about it.

Lean and Kanban can be used together in many ways to create a more effective and efficient workflow. Here are a few ways these methodologies can complement each other:

1. Combining Lean’s Process Improvement with Kanban’s Visualization

Lean’s focus on continuous process improvement can be combined with Kanban’s visual management tools to create a more effective workflow.

The Lean methodologies can be used to identify and remove waste, while the Kanban boards provide a visual representation of the workflow, making it easier to manage.

2. Improving Collaboration with Lean and Kanban

By combining Lean’s emphasis on teamwork with Kanban’s focus on collaboration, teams can work together more effectively and efficiently.

Lean helps to identify and resolve any communication problems, while Kanban provides real-time updates and visual tools to manage the flow of work.

3. Integrating Lean’s Kaizen with Kanban

Lean’s philosophy of Kaizen, or continuous improvement, can be integrated with Kanban’s iterative approach to create a more flexible and adaptable workflow.

Teams can use the Kaizen method to identify areas for improvement and implement change, while the Kanban boards provide real-time updates to help teams stay on track.

4. Incorporating Lean’s Value Stream Mapping with Kanban

Lean’s value stream mapping can help teams identify areas of waste and inefficiency in the workflow, while Kanban’s visual boards can be used to manage and improve the flow of work.

5. Combining Lean’s 5S System with Kanban

The 5S system, which is a Lean methodology for organizing and improving work processes, can be combined with Kanban’s visual boards to create a more efficient and organized workflow.

The 5S system helps teams to standardize their work processes, while Kanban provides visual management tools to manage the flow of work.

6. Integrating Lean’s Pull System with Kanban

The Lean pull system, which is a method of controlling the flow of work, can be integrated with Kanban’s visual management tools to create a more efficient workflow.

The pull system helps teams to manage demand and ensure that work is only started when it is needed, while the Kanban boards provide real-time updates on the status of work items.

Conclusion

The Agile methodology places emphasis on individuals and interactions over processes and tools, and this is the same for any approach you decide to use.

The Lean and Kanban approaches can help you to handle complex projects by creating a more efficient and effective workflow.

This article isn’t geared to pit these methodologies against one another but to provide information on how you can use and tailor them to your specific needs and goals.