Lean and Six Sigma are two popular process improvement methodologies used in project management to eliminate waste, bottlenecks, and inefficiency albeit using different approaches.

Understanding the distinctions between these methodologies allows you to leverage the best of both Lean manufacturing and Six Sigma principles for process excellence.

In this article, we’ll compare Lean vs Six Sigma over their core philosophies on identifying and tackling waste, key distinctions, and which one may be best for your needs.

We’ll also look at how to combine them in a hybrid Lean Six Sigma approach to get the best of both worlds.

What is the Difference Between Lean and Six Sigma?

Lean and Six Sigma are both process improvement methodologies that aim to eliminate waste and improve quality.

Lean focuses on speeding up processes by removing unnecessary steps, while Six Sigma uses statistical analysis to reduce variation and defects.

A key difference is that Lean is primarily concerned with flow and speed, whereas Six Sigma emphasizes reducing defects and variation through rigorous data collection and analysis.

What is Lean Project Management?

Lean project management applies Lean principles to the management and execution of projects.

Inspired by Lean manufacturing, Lean project management aims to eliminate waste, optimize workflow, and maximize value.

The core focus is on streamlining the project lifecycle by cutting out redundant and unnecessary activities that don’t directly contribute to project outcomes.

It seeks to improve flow efficiency by reducing waiting times, bottlenecks, and interruptions that slow down throughput.

Lean project management utilizes practices like continuous improvement, visual tracking, and an emphasis on fast feedback cycles.

It relies on iterative delivery versus long, sequential project phases to deliver value frequently and efficiently versus forcing stakeholders to wait until the end.

Adopting a Lean mindset means involving team members in improving their own processes. It also requires focusing on the customer perspective and defining value based on what end users care about.

Lean thinking provides an effective toolkit to enhance project outcomes, interactions, and stakeholder satisfaction. When applied properly, Lean project management principles can streamline work while improving quality and engagement.

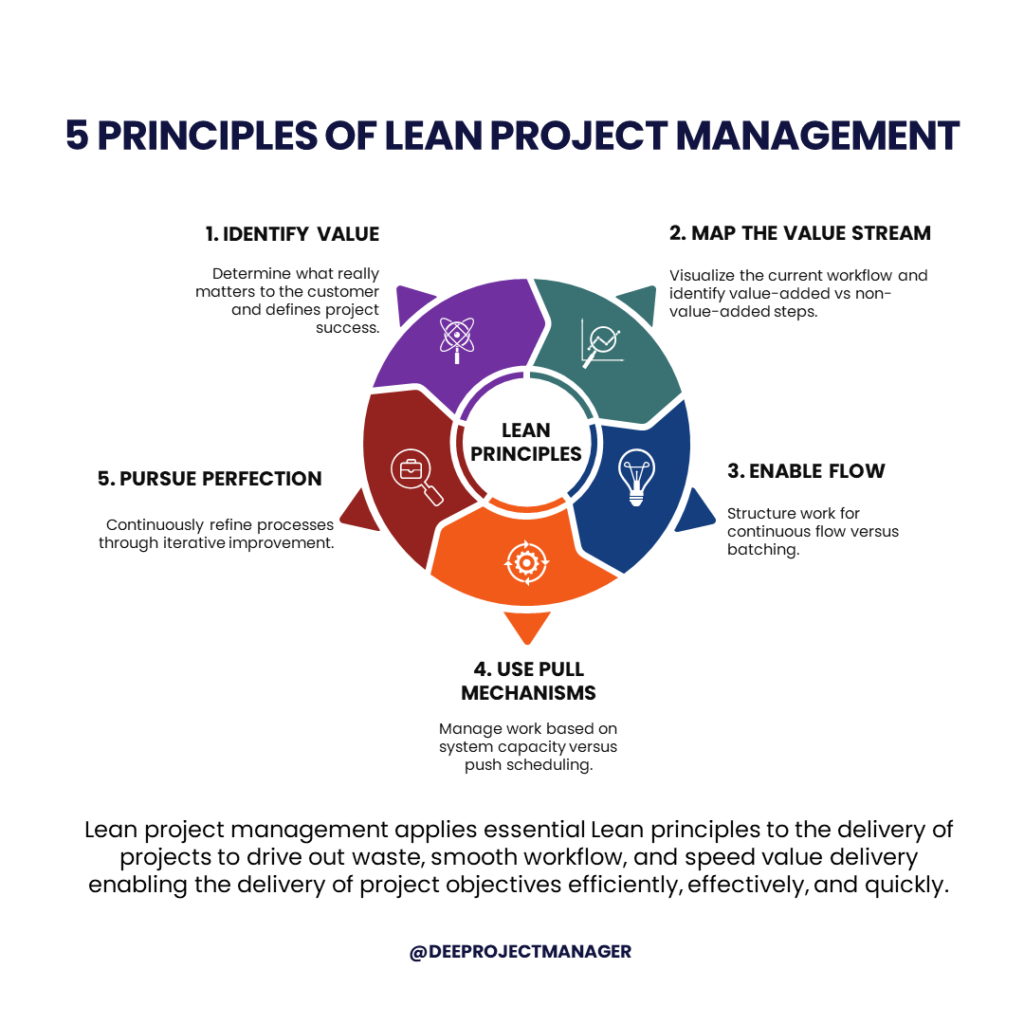

5 Principles of Lean Project Management

Lean project management applies essential Lean principles to the delivery of projects.

These core Lean tenets drive out waste, smooth workflow, and speed value delivery enabling the delivery of project objectives efficiently, effectively, and quickly.

They include:

1. Identify Value

- Determine what really matters to the customer and defines project success.

- Focus on maximizing value delivery while minimizing waste.

2. Map the Value Stream

- Visualize the current workflow and identify value-added vs non-value-added steps.

- Redesign the process to remove inefficiencies.

3. Enable Flow

- Structure work for continuous flow versus batching.

- Reduce bottlenecks, handoffs, and obstacles slowing throughput.

4. Use Pull Mechanisms

- Manage work based on system capacity versus push scheduling.

- Align work planning with customer demand.

5. Pursue Perfection

- Continuously refine processes through iterative improvement.

- Empower team members to optimize their work.

What is Six Sigma in Project Management?

Six Sigma is a data-driven approach to process improvement centered around minimizing defects and variability by using rigorous quantitative analysis to achieve stable, predictable outcomes and prevent flaws.

In project management, Six Sigma techniques help enhance quality by reducing uncertainty and risk throughout the project lifecycle.

It provides a structured roadmap for defining, measuring, analyzing, improving, and controlling key processes.

The focus is on achieving consistent results that reliably meet customer requirements. By tracking detailed performance metrics, project teams can identify the root causes of issues and develop targeted solutions.

Six Sigma relies on techniques like statistical process control, process mapping, FMEA, and hypothesis testing. Master Black Belts oversee projects while Green Belts and Black Belts lead process improvement initiatives.

While complex, Six Sigma instills project rigor and helps organizations achieve excellence by providing tools to understand process capability, reduce variability, prevent defects, and enhance project consistency.

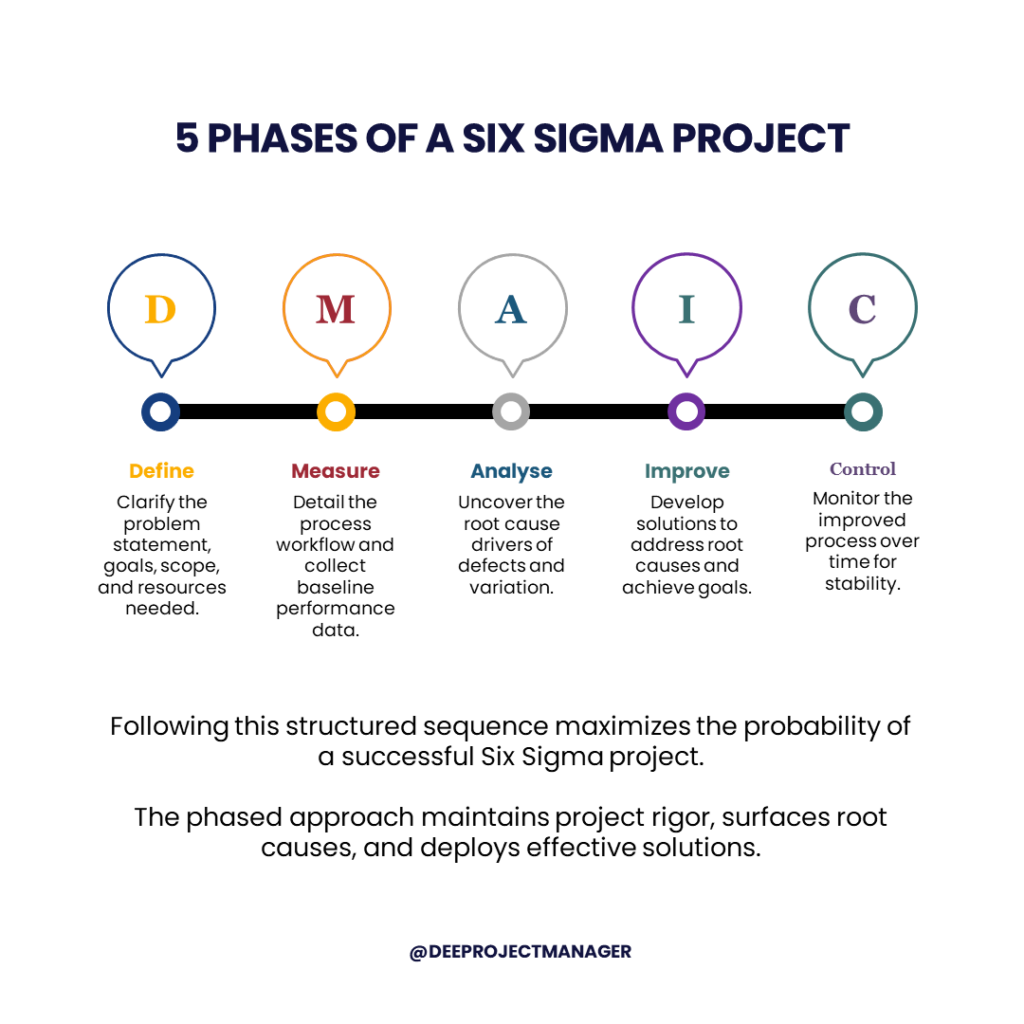

What are the 5 Phases of a Six Sigma Project?

Six Sigma projects typically follow a structured phased approach known as DMAIC.

This structured sequence maximizes the probability of a successful Six Sigma project by maintaining project rigor, surfacing root causes, and deploying effective solutions.

The 5 phases are:

1. Define

- Clarify the problem statement, goals, scope, and resources needed.

- Gather the voice of the customer data to set objectives.

- Outline high-level project timelines and team roles.

2. Measure

- Detail the process workflow and collect baseline performance data.

- Identify key input and output variables to monitor.

- Validate causes and quantify the problem with statistical analysis.

3. Analyze

- Uncover the root cause drivers of defects and variation.

- Use tools like hypothesis testing, regression analysis, DOE, and FMEA.

- Confirm vital few factors causing the problem.

4. Improve

- Develop solutions to address root causes and achieve goals.

- Pilot changes and measure improvement in system performance.

- Implement controls and training to sustain gains.

5. Control

- Monitor the improved process over time for stability.

- Standardize procedures, documentation, and training.

- Transition ongoing management and continuous improvement.

Lean vs Six Sigma Differences

Now let’s do a Lean vs Six Sigma head-to-head comparison to see their differences across various aspects.

Definition of Waste

The first major difference lies in how Lean and Six Sigma define waste. For Lean, waste refers to any activities or processes that do not directly add value for the customer. The focus is on eliminating steps that are non-value adding to improve workflow.

In contrast, Six Sigma defines waste as defects or variability within a process. The goal is to reduce inconsistency and variation that can lead to errors or poor quality.

Lean targets waste from the customer perspective – anything that doesn’t contribute to a useful outcome. Six Sigma targets internal process waste by minimizing flaws and exceptions.

Historical Origins

Lean and Six Sigma also differ in their origins. Lean originated from the Toyota Production System and emphasizes efficient manufacturing flow. It aims to eliminate waste by optimizing workflow.

Six Sigma was pioneered at Motorola with a focus on reducing variability and defects through statistical analysis. It uses data to minimize inconsistencies.

This impacts how practitioners approach improvement. Lean looks to streamline flow while Six Sigma relies on quantitative data.

Implementation Approaches

There are also differences in how Lean and Six Sigma are implemented. Lean is a mindset and cultural practice that engages all employees in improving their own workflows. It is best integrated through grassroots change.

Six Sigma follows a structured, top-down methodology requiring specialized training and certifications and relies on technical statistical techniques.

Lean emphasizes employee engagement and ownership while Six Sigma requires technical proficiency and expert-led project execution.

Application

Finally, Lean and Six Sigma differ in where they are best applied. Lean can work in almost any function given its focus on flow and waste. It originated in manufacturing but now applies broadly.

Six Sigma on the other hand has roots in complex manufacturing and may not suit processes with high variability or that require flexibility.

Similarities Between Lean and Six Sigma

Despite the aforementioned differences, Lean and Six Sigma share an overarching drive towards maximizing quality, and efficiency, and reducing operational waste.

Some key similarities include:

Shared Goal

The core goal of both Lean and Six Sigma is to eliminate waste and optimize processes to be as efficient and effective as possible.

Whether targeting non-value adding steps (Lean) or defects (Six Sigma), the end objective is enhanced workflow and quality. Though their definition of waste differs, their ultimate aim is the same.

Data-Driven

Both methodologies rely heavily on data analysis to identify improvement areas and validate results.

Lean analyzes value stream mapping and metrics like takt time, and Six Sigma uses statistical analysis and capability studies. Data provides objective insights to spur and support process changes.

Continuous Improvement

A core tenet of Lean and Six Sigma is continuous incremental improvement over time, not one-time solutions.

They involve constantly inspecting processes, making small optimizations, and tracking impact to sustain ongoing gains versus temporary fixes.

Lean vs Six Sigma: Which Should You Use?

There is no universal best approach and it all depends on the context of your project. Lean and Six Sigma can complement each other when applied selectively to play to their individual strengths.

When choosing between Lean and Six Sigma, consider several factors:

Type of Waste/Defects

Consider if waste is from poor flow or high variation.

- If waste comes from uneven workflow or lack of value, Lean may be better to smooth flow.

- If waste stems from process variability causing defects, Six Sigma offers tools to minimize inconsistency.

Project Goals

Align methodology to project goals and outcomes.

- If the goal is fast project throughput and rapid delivery, Lean provides lightweight techniques to remove bottlenecks.

- For complex projects with strict quality requirements, Six Sigma provides rigor to achieve near-zero defects.

Team Skills

Assess if the staff have the skills to support each approach.

- Lean requires team engagement and motivation to optimize processes.

- Six Sigma relies on technical expertise in statistical tools and analysis.

Organizational Culture

Consider organizational dynamics to determine fit.

- Lean thrives in agile, collaborative organizations open to grassroots change.

- Six Sigma needs structure, top-down leadership support, and commitment to rigorous metrics.

The Hybrid Approach: Lean Six Sigma Methodology

Lean Six Sigma combines concepts from both Lean and Six Sigma to improve process speed and quality. It aims to optimize workflow while reducing defects and variation.

Lean Six Sigma utilizes tools from each methodology that address different types of waste or constraints:

- From Lean, it applies techniques to smooth workflow, eliminate bottlenecks, and speed up cycle time. For example, value stream mapping, Kaizen events, Kanban, and 5S.

- From Six Sigma, it employs data-driven tools to reduce variability and defects. Some examples are statistical analysis, FMEA, SPC, and DOE.

A Lean Six Sigma project will typically follow the DMAIC (Define, Measure, Analyze, Improve, Control) framework used in Six Sigma. However, the toolbox draws from both methodologies.

Lean Six Sigma requires cultural adoption of continuous improvement like Lean as well as technical expertise in statistical tools per Six Sigma. Training is provided for different belts similar to Six Sigma.

The hybrid model allows organizations to balance speed of delivery and consistency. Lean Six Sigma lets you streamline processes for fast flow while also statistically controlling them to prevent defects.

It provides structured, data-backed techniques to:

- Improve process speed by reducing waste

- Minimize variability and quality issues

- Engage cross-functional teams in optimization

Lean Six Sigma delivers the benefits of each methodology in a holistic approach. It is popular in manufacturing, healthcare, financial services, technology, and other industries seeking accelerated flow with quality as the combined model yields process excellence.

Final Thoughts

Lean and Six Sigma provide complementary approaches for driving process improvement.

While differing in their view of waste and implementation tactics, both methodologies add value by enhancing flow, reducing defects, and engaging teams.

Organizations can realize benefits by selectively applying Lean and Six Sigma tools based on project goals and business context.